To provide enabling capabilities for fabricating advanced nanoscale structures with novel properties

The Nanoscale Synthesis and Characterization Laboratory (NSCL) is making advances in science at the intersection of physics, materials science, engineering, and chemistry. Nanoscience, the term applied to research at this intersection, involves synthesis, characterization, and manipulation of nanoscale structures, objects, or features. Initially, work at NSCL focused on designing and developing innovative new materials and structures for use targets for the National Ignition Facility (NIF) laser. Projects have included developing new high-strength nanocrystalline alloys, graded density materials, and high Z nanoporous structures. NSCL has also recruited and trained personnel for LLNL programs such as the NIF, Strategic Deterrence, and Global Security directorates.

NSCL is pursuing science and technology in the following areas:

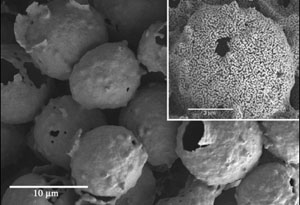

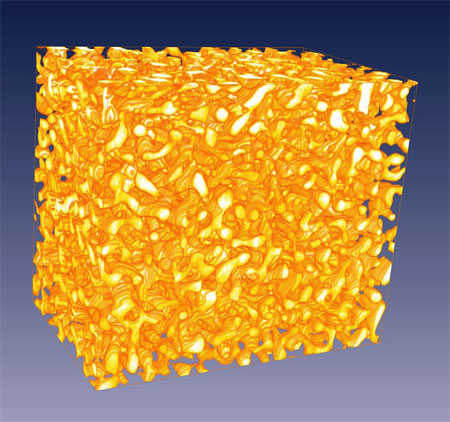

- Nanoporous materials—We discovered, developed, and refined an array of synthesis approaches for nanoporous metals with relative densities below 25% and pore sizes on the nanometer-length scale. Nanomechanical characterization techniques have led to the exciting discovery of unusual high strength nanoporous metals.

- Advanced nanocrystalline materials—We used electrodeposition and sputtering techniques to successfully synthesize nanocrystalline Au/Cu alloy and body-centered-cubic (BCC) Ta. Both of these materials exhibit excellent hardness and tensile strength properties. The deformation mechanisms of these materials with grain sizes of 10–20 nm and below are being addressed through experiments and molecular dynamics models.

- Novel three-dimensional (3D) nanofabrication technologies—We established new tools for 3D fabrication such as focused ion beam processing and proximity field nanopatterning.

- Nondestructive characterization at the mesoscale—We are establishing new tools in x-ray imaging and scattering techniques to provide nanoscale to microscale characterization.

The NSCL is also pursuing new science and technology with the focused ion beam facility.

State-of-the-Art Technologies

NSCL pioneered three techniques for synthesizing ultralow density metal foams that, combined, led to a breakthrough allowing us to synthesize 1.5% relative density gold foam. Figure 2 shows scanning electron micrographs of a fracture surface from a gold/silver monolithic foam made by filter casting of Au/Ag coated polystyrene spheres. The polystyrene is removed by annealing the monolithic structure for 1 hour at 300°C. Dealloying removes the silver and a pure gold foam remains (inset).

We continued to develop the science and technology for crystalline carbon (diamond) ablator capsules. Working in collaboration with theFraunhofer Institute for Applied Solid State Physics, we developed techniques to produce 500-µm-diameter nanocrystalline carbon shells. Figure 3 shows a photograph of one batch of these diamond ablators, comparing NIF to OMEGA-sized ablators.

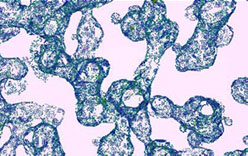

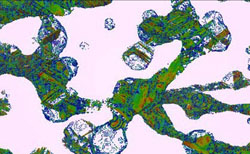

We investigated the novel mechanical properties of nanoporous materials using molecular dynamics simulations of gold foams in tension. Figure 4 shows the propagation of dislocations across gold ligaments as tensile stress is applied.

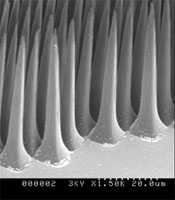

The NSCL is also developing 3D structures using lithographic techniques. Figure 5 shows an example of the use of deep reactive ion etching of silicon through an oxide mask and then filling the etched structure with polymer. The cured polymer structure is released from the silicon structure by isotropic wet etching of the silicon.

We are continuing to research small angle x-ray scattering to characterize nanoscale structures that cannot be probed by imaging techniques. We also are exploring the "bottoms-up assembly" of nanomaterials and components using electrophoretic deposition from aqueous nanoparticle solutions. We will pursue progress in diamond science to ready the diamond ablator capsule technology. Au/Cu capsule fabrication with strength and permeability is still a high priority.